SHOCK-BLOWER®

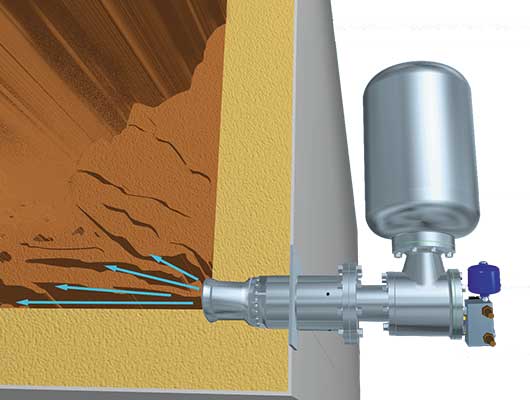

Efficiently clear material deposits

- Reactivate your existing silo capacities

- Clear deposits in pipes

- Prevent the occurrence of channels in silos

Systematic perfect aim

The SHOCK-BLOWER®

For over 35 years now, buildups of bulk solids have been successfully cleared with the SHOCK-BLOWER® air blast system.

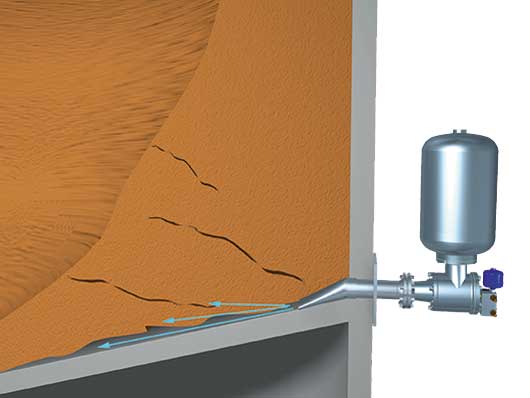

How does the SHOCK-BLOWER work?

Clear deposits in pipes

Individual customization

AGRICHEMA SHOCK-BLOWER®s comprise a storage tank for compressed air or inert gas, and a valve unit with control unit.

The compressed air tank is manufactured in accordance with EURO standards, and is hot dipped galvanised inside and out. The valve unit with its valve seat made from CrNi steel is found protected inside the tank, yet can still be quickly and easily monitored and serviced from outside. The extensive piston’s stroke movements, for opening and closing the exhaust opening, occur in milliseconds, and the blasts of air achieve optimum results thanks to their explosion-like nature.

The piston is fitted with special guiding sealing rings, enabling the piston’s stroke movements to occur in just milliseconds, so that the explosion-like blasts of air achieve optimum effect. AGRICHEMA’s SIKOBETIC® control unit ensures the air blast devices operate reliably (even with strong fluctuations in the compressed air supply). What’s more, the SIKOBETIC® offers ease of use and the greatest possible safety for operators.

SHOCK-BLOWER® with energy-saving effect

SHOCK-BLOWER® air blast devices with hot-dip galvanised compressed air tanks and valve seats made from CrNi steel have been designed for a long service life and high levels of operational safety. Thanks to the unique valve technology, which pneumatically closes the piston in just milliseconds, you can save up to 50% compressed air/power.

Personal consultation on

+49 (0) 6707 9140 46

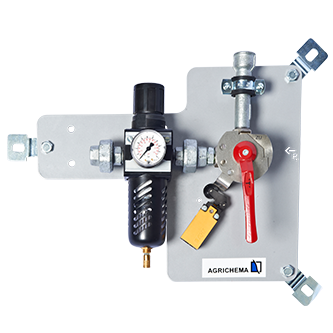

The accessories

SIWARTIC®

AGRICHEMA’s SIWARTIC® with filter regulator and 3-way closable 3/2-way ball valve is used as a safety and maintenance unit for reliable forced venting of the SHOCK-BLOWER® systems. Optional: Pressure monitor/Pressure transmitter for monitoring the compressed air.

Automatic cycle control (ATS)

The automatic cycle control (ATS) for SHOCK-BLOWER® is freely programmable. Bulk solids problems can therefore be resolved by individual control of the SHOCK-BLOWER®.

Other accessories

Air lines, connection sets and installation accessories.

SHOCK-BLOWER® System POWERPACK

Tried and tested methods

Tested procedures

Standardised technology

More safety, more productivity.

Your expert contact people for

SHOCK-BLOWER

Fabio Fregapane

f.fregapane@agrichema.de

+49 (0) 6707 9140 46

Heidi Reimer

h.reimer@agrichema.de

+49 (0) 6707 9140 14

Sara Esser

s.esser@agrichema.de

+49 (0) 6707 9140 52

Satisfied costumers:

Service without compromise

AGRICHEMA regards itself as a complete service provider when it comes to bulk solids.

Do you have questions or need support for your bulk solids plant?

Place inquiry

Our contact persons will help you with words and deeds. Please call us or send your inquiry.

T: +49 (0) 6707 91 40 0

F: +49 (0) 6707 91 40 11