AGRICHEMA – A success story

At the end of the 1970s, a large fertiliser company in Mainz-Budenheim, Germany, which belonged to the Oetker Group, was faced with this problem.

Bridging and grating buildups in bunkers and silos cause production errors and affect a company’s economic efficiency.

The beginnings

That was the starting situation, and for the committed technical manager Udo Leibling, a challenge.

After tests with various discharge aids didn’t deliver the desired results, he himself developed an air blast technology based on the highest criteria when it came to quality, reliability and operational safety.

From practical experience, for practical use

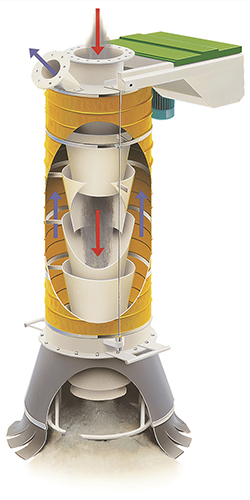

The principle: When required, compressed air (up to 10 bar) stored in a container is released, explosion-like, through special air blast systems into the area between the bulk solids and the container wall.

This loosens the bulk materials from the wall and transports them in the direction of the outlet.

That was the birth of the SHOCK-BLOWER® technology that is so successful today, and at the same time, the idea ‘from practical experience, for practical use’ was born; to develop and market innovative solutions for the bulk solids industry.

The expansion

On October 1st, 1980,

agricultural products, Industrial products and chemical needs,

which had been dormant since the 1970s) was reactivated, with a new business activity: ‘Machinery for the bulk solids industry’.

The managing director was Udo Leibling, whose name is closely bound up with the company’s history and AGRICHEMA’s success.

In 1981,

the first SHOCK-BLOWER®s were sold, and the firm was renamed ‘AGRICHEMA Materialflusstechnik’ (AGRICHEMA material flow technology).

In 1982 / 83

In 1984,

it became apparent that preheater systems in rotary kiln systems in the cement industry were operated in three-shift patterns, and had to be cleaned manually.

The systems were fitted with SHOCK-BLOWER®s, and the deposits in the high temperature zones could largely be cleaned completely automatically, which increased the systems’ economic efficiency.

This is how the SHOCK-BLOWER® technology began its triumphant spread throughout Germany and beyond.

In 1985,

In 1986

saw the presentation of a redeveloped SHOCK-BLOWER for use in high temperature zones, and in 1987, AGRICHEMA presented itself for the first time at the international trade fair in Hanover.

During 1988 / 89,

AGRICHEMA searched for and found cooperation partners elsewhere in Europe, and awarded a licence for manufacturing of the TELESCOPER®.

–

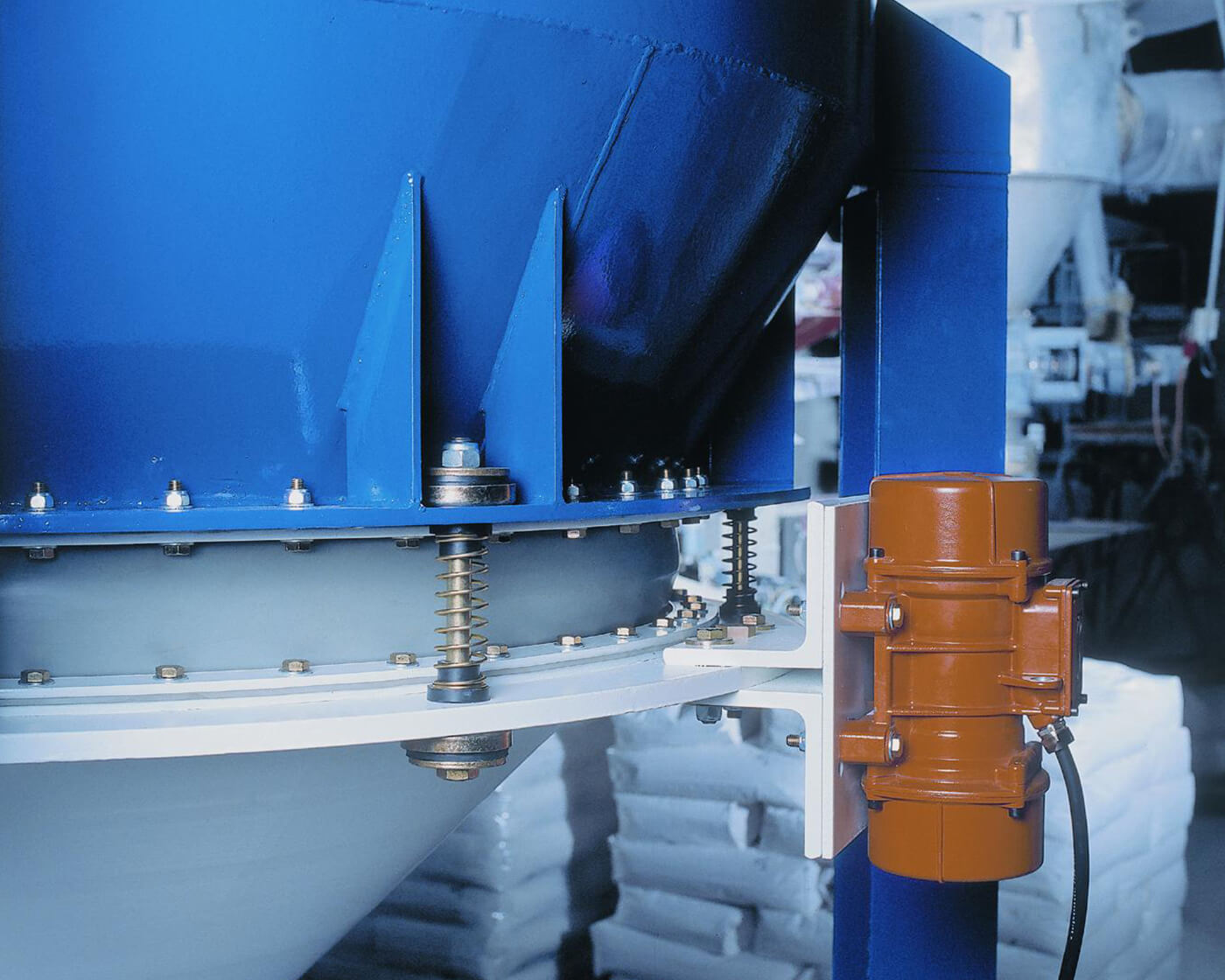

At the same time, AGRICHEMA won exclusive German distribution rights for the VIBOSTAR®.

The success story

Thanks to the high quality and reliability of its products, as well as the company’s comprehensive knowhow and individual consultations, even by the start of the 1990s AGRICHEMA was already one of the recognised partners in the bulk solids industry.

Thanks to the SHOCK-BLOWER® technology, the company became market leader in Germany.

Today, as well as brand names, AGRICHEMA possesses numerous national and international trademarks.

AGRICHEMA isn’t a manufacturing company, but has its products manufactured under contract. It is responsible for their conception, part of the final assembly works, as well as installation on site.

It can be said with certainty that this company philosophy has played a decisive role in the company’s economic success.

In April 2004, AGRICHEMA moved into a new office complex, featuring warehouse facilities and an assembly shop, in the Waldlaubersheim business park. It is conveniently situated directly next to the A61 motorway.

2016 saw a change of name.

Today, the company is called:

AGRICHEMA Schüttguttechnik GmbH & Co. KG

The new addition to the name (‘Schüttguttechnik’ – bulk solids technology) makes it considerably easier for the reader to establish what field of activity the business is active in.

2020

Managing Director Udo Leibling retired on the anniversary.

The company will be continued by Michael Roth as Managing Director, as well as the authorized signatories Christian Braun and Steffen Mahfoud-Wahl.

The thanks

On the one hand, the AGRICHEMA success story over the last 40 years has only been due to the industriousness, commitment and inventiveness of the meanwhile 35 employees.

But on the other, it is also due to our cooperation partners and their professional work.

An especial thank you to our many customers, without whom this success story would not have been possible.

The company management would therefore like to thank every single one of them.

Do you have questions or need support for your bulk solids plant?

Place inquiry

Our contact persons will help you with words and deeds. Please call us or send your inquiry.

T: +49 (0) 6707 91 40 0

F: +49 (0) 6707 91 40 11