Loading chutes

Dust-free loose loading thanks to innovative solution

- Now you too can load in an environmentally friendly manner

- Dust-free, emissions-free reliability

- Future-proof, thanks to flexible modular technology

Loading chutes

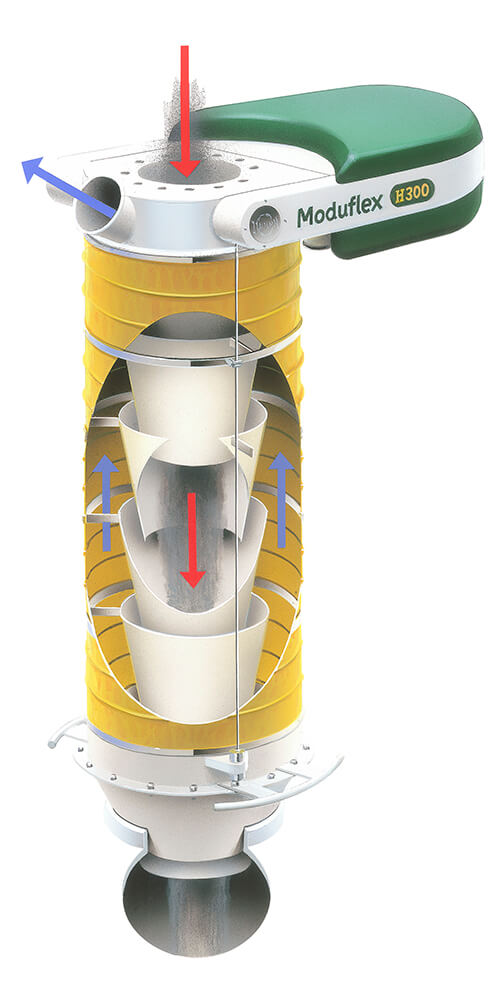

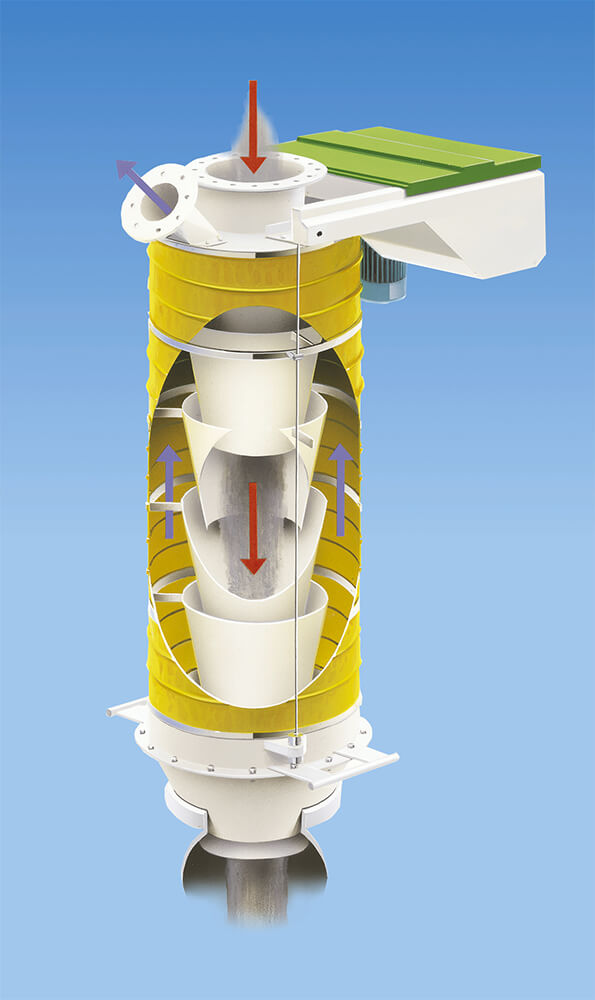

- Infeed with drive station

- Modular section with chute modules on the outside and bulk solids guide cones inside

- Outflow head

Systematic clean affair

With the MODUFLEX product range, we can offer the appropriate solution for any application. Tailor-made solutions according to customer requirements are also available.

Personal consultation on

+49 (0) 6707 9140 53

Examples of use

- Building materials

- Chemicals

- Fertilisers

- Colouring agents

- Moulding sand

- Animal feed

- Gypsum

- Limestone

- Coal

- Clinker bricks

- Plastics

- Minerals

- Foodstuffs

- Washing powders

- Cement

- Intermediate products

How it works

This means lower maintenance and operating costs.

The design of the loading system varies according to the following criteria:

We would be pleased to help you select the product that best meets your needs.

Loading chutes with filters

Type F

Bag filter

Type F is a compact solution that does not require an external filter.

The inlet is fitted with an integrated filter module comprising 9 filter hoses.

The filter surface is 2.5 m²

The filter inlet is fitted with a separate ventilator with regulating damper and compressed air tank, which ensures that the filter is continuously cleaned.

Type D

Cartridge filter

The Moduflex inlet type D has the same properties as the inlet for type F.

The difference is that the inlet is fitted with an integrated filter module comprising 9 filter cartridges.

The filter module requires a certain installation height, but the filter cartridges offer a larger filter surface than the filter hose.

The inlet is available in 300 mm or 400 mm diameter variants.

Type K & N

Side filters

The K & N series are fitted with a filter fitted to the side.

Their design enables easy assembly and maintenance of the separate filter unit.

What’s more, this solution enables the use of larger filter areas than types F & D.

Closed loading

- The discharge cone is fitted to the tank lorry’s dome cover, and therefore forms a closed connection

- The material stream falls freely through the guide cones inside

- The displaced air escapes, or can be extracted, through the annular gap between the outer tube and internal product guide cones

- A fill level detector installed in the outfeed stops loading when the tank lorry is full

Open loading

- The loading outlet rests on the bulk solids cone

- The material stream falls freely through the guide cones inside

- An installed fill level detector automatically raises the outlet and the meanwhile full material cone

Combined loading

- The combined loading system is a combination of open and closed loading

- The multi-outlet comprises cone and dust skirt, and is suitable for loading not just silo lorries but also open vehicles and containers

- Depending on the application, the dust skirt is either at the bottom or the top

- The skirt can be raised either electronically or manually

We would be pleased to help you select the product that best meets your needs.

Your expert contact people for

Moduflex

Anna-Lena Ohmenzetter

a.ohmenzetter@agrichema.de

+49 (0) 6707 9140 53

Michael Marbé

m.marbe@agrichema.de

+49 (0) 6707 9140 28

Erwin Haßdenteufel

e.hassdenteufel@agrichema.de

+49 (0) 6707 9140 36

Satisfied costumers:

Service without compromise

AGRICHEMA regards itself as a complete service provider when it comes to bulk solids.

Do you have questions or need support for your bulk solids plant?

Place inquiry

Our contact persons will help you with words and deeds. Please call us or send your inquiry.

T: +49 (0) 6707 91 40 0

F: +49 (0) 6707 91 40 11