SHOCK-BLOWER®

Efficiently clear material deposits

- Reactivate your existing silo capacities

- Clear deposits in pipes

- Prevent the occurrence of channels in silos

Systematic perfect aim

Wherever bulk solids are manufactured, processed or stored, bunkers and silos are the starting points for automated operations.

At normal temperature range

How it works

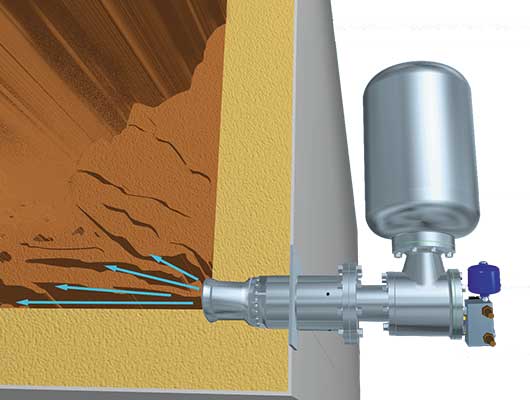

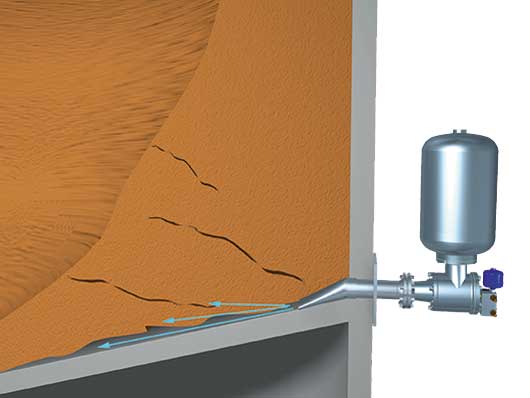

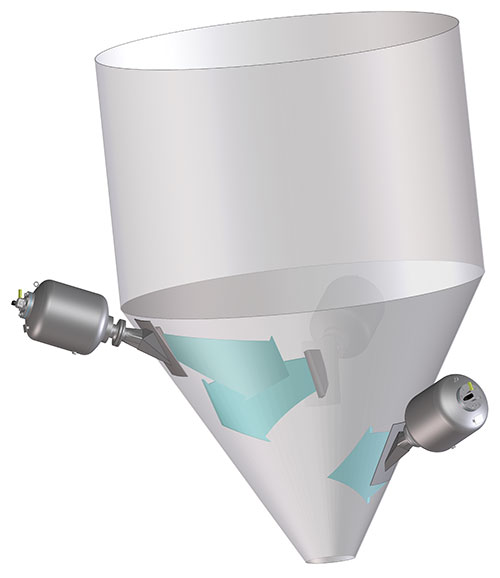

Because the explosion-like air blasts are targeted specifically in the area between the bulk solids and the wall using special expansion guide nozzles, the bulk solids are ‘husked’ by the wall and moved in the direction of the outlet.

Personal consultation on

+49 (0) 6707 9140 46

Flow problems resulting from bridging and channel formation have a considerable effect on the efficiency of your plant.

Bridging

Channel formation

We would be pleased to help you select the product that best meets your needs.

Examples of use

- Bunkers, silos and tanks made from concrete, steel, aluminium or plastic (also flat-bottomed round and square tanks)

- Star-shaped bunkers and rows of bunkers

- Stockpiles

- Transfer funnels and chutes

- Filter systems and pipelines

- Spray towers

- Cyclones

The size and number of SHOCK-BLOWER®s and air blast systems to be used depends upon:

- The bulk solids’ properties

- Local conditions

- The type and shape of the deposits

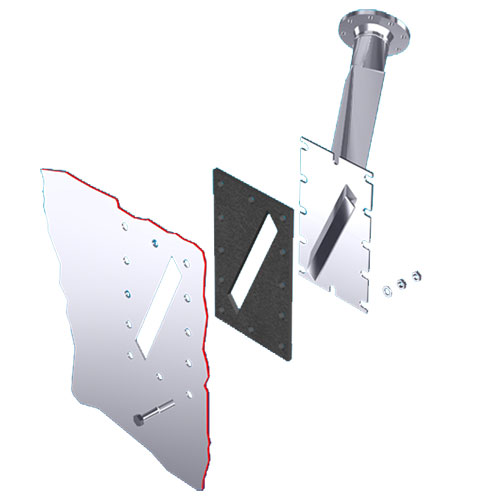

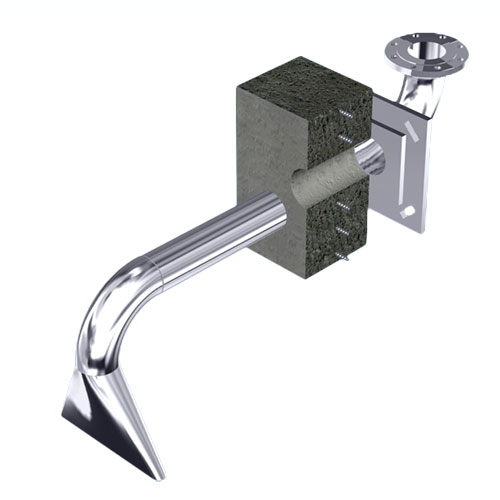

Expansion guide nozzles for the normal temperature range

AGRICHEMA’s versatile expansion guide nozzles guarantee individual solutions for the error-free operation of bulk solids systems.

Tangential

Hidden

Your expert contact people for

SHOCK-BLOWER

Fabio Fregapane

f.fregapane@agrichema.de

+49 (0) 6707 9140 46

Heidi Reimer

h.reimer@agrichema.de

+49 (0) 6707 9140 14

Sara Esser

s.esser@agrichema.de

+49 (0) 6707 9140 52

Service without compromise

AGRICHEMA regards itself as a complete service provider when it comes to bulk solids.

Do you have questions or need support for your bulk solids plant?

Place inquiry

Our contact persons will help you with words and deeds. Please call us or send your inquiry.

T: +49 (0) 6707 91 40 0

F: +49 (0) 6707 91 40 11